Inspirations of a factory tour in Louisville

12 years ago, the boss I worked for always tried to say that better management will make his business and all of us more successfully, and I am the person who was supposed to help him to manage the company and team better, of course I do not think that is what I can do much when I only have one year working experience. This trip in US really makes me re think of so called management issue, forgetting about the political difference, US has been greatly automated compared to China. That is not all about to use more machinery instead of man power, but more means all business and industry processes are in one integrated system, and sub-systems under bigger system.

It has been a hard time for me to persuade our CTO and other developers use a project management system rather than using instant messenger, I think same thing as the Qing Dynasty will never adopt western technology until the west use those techs crack them down, hard lesson, which one can not afford if you want to be successful in business world.

I visited a Casey’s factory when I was in Louisville last Tuesday, with the guarding of Casey, I think can at lease sum up following useful points which may help me think further onto this issues:

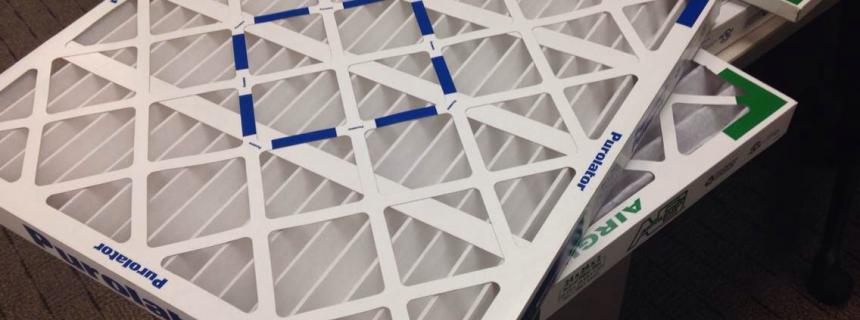

1. Do what you can do only. This factory is one of division of a company who do air filtration products only, and they even bought product lines from GE to make help them increase their competence in this industry. No business has high thresh hold of entrance when there is no competition, but when competitions available, you must focus on the things you can do, you enjoy to do, and you can do best.

2. To build up or create an automation system of course will help the productivity, but they only need to be done when the cost can be justified, Casey told me one of their CEOs had to leave when an R&D project of 6 million failed to achieved any benefits to factory. Some lines still use pretty much manual way since it is not worthwhile to buy or build a machine for it.

3. To make a system work need training and cooperation of the whole team, from CEO to operators, it may need some one adopts it first and develop it into mature model, then apply to whole team.

4. Automation require a system, that is the cost and foundation, but once it is set up, it will become the gold mine of business as long as the sales can bring that much business leads, since the productivity is so great! The world is dominated by US company largely because US companies have great system, for example, McDonald can provide 24 hours fast food in very good location and very stable quality, and the people working there do not need much savvy but just follow the procedures to press the button and saying “I am loving it”, and that is it!

5. To help people use a good system may need convince folks that how system can help them, and they should respect the rules they have to obey to work under a system, that seems the hard part I can make it happen.

The picture were taken in that factory, huge one, but fully organized.

沪公网安备 31010102006360号

沪公网安备 31010102006360号